Quality Control with AI (Artificial Intelligence) 9V

Are you a school or company and do you want to order on account? Please contact us.

Description:

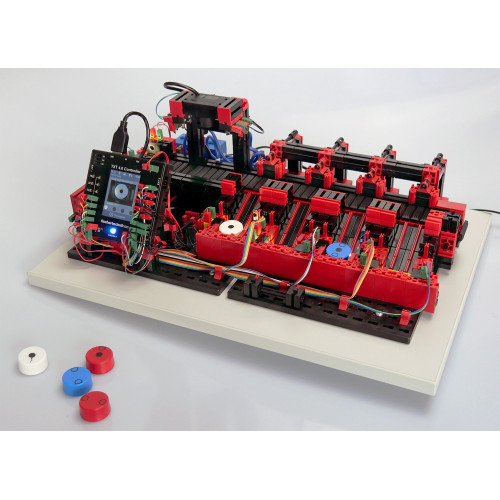

The use of artificial intelligence in industry, education and research is becoming increasingly important. To visualize this complex topic hands on, the model “Quality Control with AI” is ideally suited. A sustainable learning experience is created thanks to the linking of theory and practice. Especially in quality control, AI brings many advantages, which are already being used e.g. in the automotive industry. Processes can be shortened, error rates and costs minimized, and error evaluation standardized. The fischertechnik sorting system is supplied with workpieces in three different colors. These workpieces are marked with three processing features as well as different defect patterns. The workpieces are scanned by the camera and classified using the trained AI. Depending on the color, feature and defect pattern, the workpieces are then sorted by the artificial intelligence based on their quality characteristics. The AI used is implemented with machine learning in Tensorflow, where an artificial neural network was trained with image data. The learned AI is executed on the fischertechnik TXT 4.0 controller. The flow control of the model is implemented in the programming environment ROBO Pro Coding and in Python.

Hard facts:

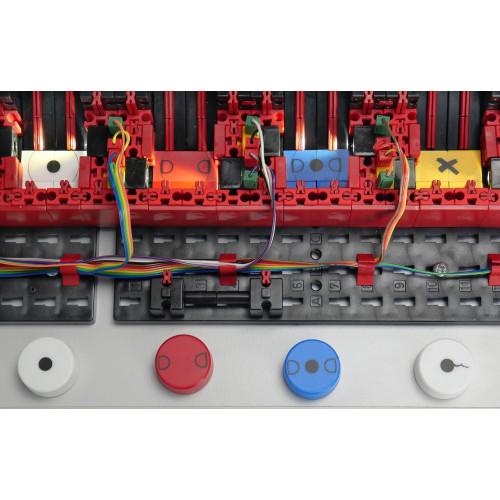

Sorting system for workpieces in 3 different colors (white, red, blue), with 3 different machining features (bore, milled-out holes) as well as different defect patterns (bore out-of-round, bore missing, milled-out holes missing completely or partially, cracks in the workpiece). These machining and defect features are simulated with corresponding adhesive labels on the workpieces. The workpieces are scanned by the camera and classified using the trained AI. Depending on the color, feature and defect pattern, the workpieces are then sorted into 4 different bays. The AI is implemented with Tensorflow and is run on the TXT 4.0 controller. Own AI models can also be generated. The training is done on a computer in Python. A corresponding example project is provided. The sequence control for the sorting system is implemented in the programming environment ROBO Pro Coding and in Python.

Essential components / highlights:

TXT 4.0 controller

USB camera

Encoder motor

Compressor

Four 3/2-way solenoid valves

Four pneumatic cylinders

Five photocells (five phototransistor & five photocell LED)

Four LED’s for camera field illumination

24 workpieces.

| Documentation 568416 | Download |