Multi Processing Station With Oven 24V

Multi Processing Station With Oven 24V

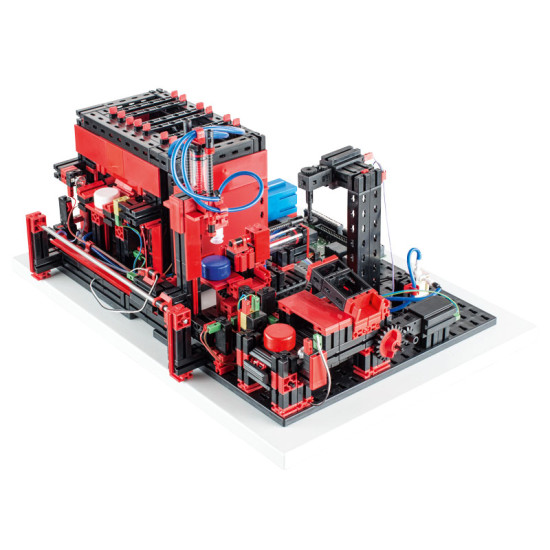

Oven with pneumatic sliding door. Downstream processing station with pneumatic transfer system including suction gripper, milling machine with turntable, and conveyor belt.

Connection to PLC control: The model has a circuit board with relays for reversing the direction of rotation of the motors. All inputs and outputs are available on both a jack plug (26-pin, 2.54 mm pitch) and on series terminals with push-in terminals.

Top Features:

- Ideal training, simulation, and demonstration model for education, further education, industrial automation, and Industry 4.0/digitalization.

- Already assembled, stable training model.

- Mounted on a stable wooden plate, packaging of the model in sturdy cardboard.

- Optionally available in the 9V standard voltage as well as in the worldwide 24V industrial standard.

- CAUTION: absolutely necessary for operation is a PLC control 24V.

Included in the training model:

- 4x Mini Motor (DC motor)

- 6x Push button (limit switch)

- 2x Phototransistor

- 2x Light barriers LED

- 4x Solenoid valve

- Compressor

Current consumption: I = approx. 1.6A

Digital inputs: 9

Outputs 24V: 14

| File name | Size | Action |

| Circuit Layout / Belegungsplan 536632 | 411.82KB | Download |

Showing 1 to 1 of 1 (1 Pages)

€968.00

Ex Tax: €800.00

- Stock: In Stock

- Model: 536632